A metal spray coating solution has extended the life span of a Labyrinth casing, thereby avoiding the need for costly replacement, leading to significant cost savings for Eskom, at its Palmiet Hydro installation.

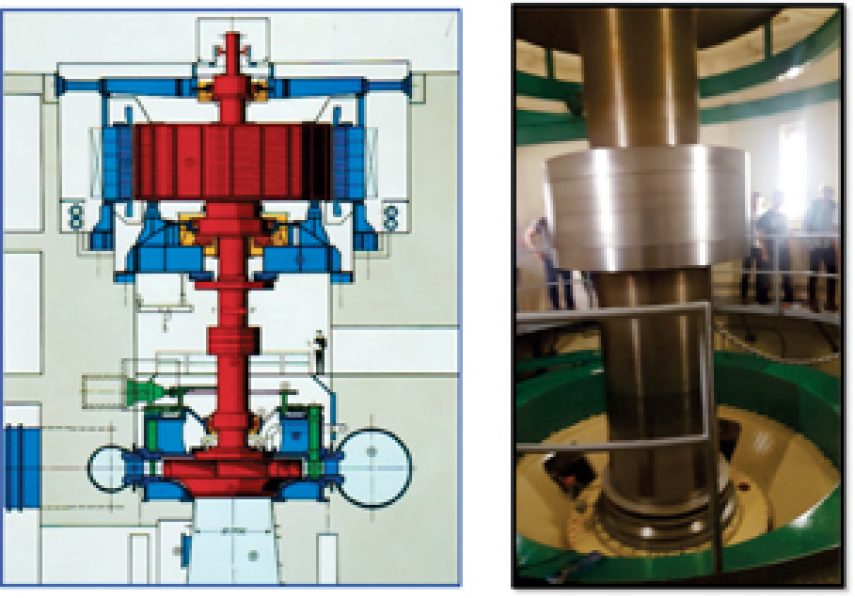

The power station is located near Grabouw in the Western Cape on the Palmiet River, 2km upstream of the Kogelberg Dam wall. The Palmiet Pumped Storage Scheme is part of a water transfer system. For generating purposes, water is released from the upper Rockview Dam to the two reversible pump turbines located 60 metres below ground level.

Surcotec was requested by Eskom to submit a recommendation and procedure to prepare and coat the top runner Labyrinth on unit 1 of the Turbine at Palmiet.

“The casing base material in the Labyrinth area of the turbine which is approximately three metres in diameter, was showing signs of accelerated erosion due to a design issue,” said Ian Walsh, Sales and Marketing Manager at Surcotec, a surface coating technology specialist based in the Western Cape.

“Consequently, the customer was experiencing severe material losses in the Labyrinth area and was forced to consider a complete and costly casing replacement.”

The Labyrinth area of the casing is an integral part and could therefore not be removed for repair without dismantling the complete unit which would have been both a cost-prohibitive and logistically impractical exercise.

Walsh added that an in-situ weld repair was not a viable option either due to the possibility of distortion.

Surcotec recommended metal spray as the most practical and cost-effective solution. “With the correct alloy being applied the coating would not only be an ideal repair solution but will also be an improvement on the original part,” noted Walsh.

With only a short window of opportunity during the plant’s scheduled outage, the Surcotec site team was mobilised and established a contained work area. With limited access and given that the work area is 70 metres below ground level, several logistical challenges had to be overcome prior to commencing with the repair.

Due to the possibility of the blast process interfering with adjacent parts, Surcotec utilised a blasting process known as ‘sponge blasting’ to contain the media and stop any ingress to sensitive areas of the turbine whilst still ensuring that the correct preparation and blast profile was obtained.

Walsh said that the selection and deposition of specialised alloys using the twin wire arc system was applied with great success. “The turbine was returned to the customer on budget and within the agreed time frame.”

According to Walsh, when the turbine was opened for routine inspection twelve months later, the Labyrinth area was found to be in perfect condition with no loss of material. “This was particularly impressive given the fact that prior to the coating application, the customer was experiencing severe material losses on the Labyrinth area over the same period.”

He said Surcotec’s metal spray coating not only prevented the need for replacement of an expensive part but also extended the life of the repaired part beyond its design resulting in substantial savings for Eskom.

The company was subsequently invited to apply the coating to unit 2 at thesame installation which Walsh said was again completed to the customer’s satisfaction.