IN an oil refinery, there are up to 23 points where the level of hydrogen needs to be very accurately monitored, both for safety and to optimise operations.

That’s according to Ian Fraser, MD of RTS Africa Engineering, a Tshwane-based company specialising in technologies which provide solutions to industrial challenges. Among other things, the company has been involved in supplying hydrogen production and analysis equipment for many years.

“Process engineers need to know the exact percentages of hydrogen at these points, in order to monitor the exact performance of the process and to also continuously optimise these processes,” Fraser added.

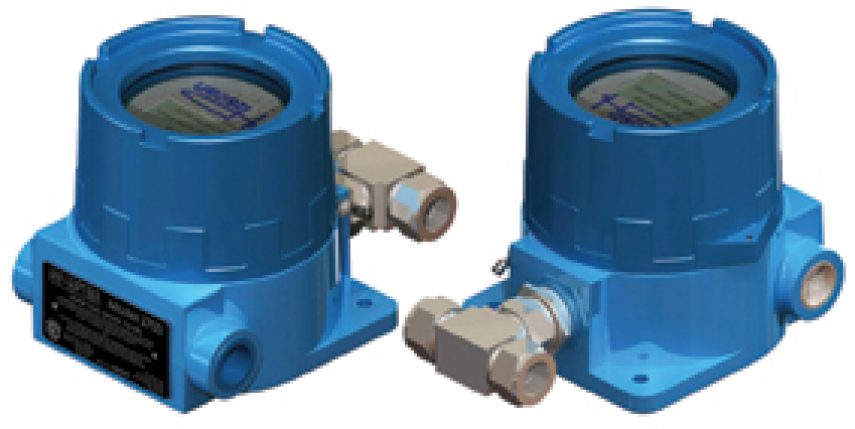

To carry out this monitoring, many oil refinery process engineers use the Hy-Optima 2700 gas analyser from RTS Africa’s US principal H2Scan.

“In the sensor of this device, a thin-film palladium/ nickel-based lattice desorbs hydrogen as it encounters the sensor. As hydrogen is absorbed into the metal lattice, the bulk resistivity of the lattice changes, allowing for accurate measurement of hydrogen levels in particular process streams.

The Hy-Optima’s solid-state, non-consumable sensor provides real-time continuous hydrogen concentration data. “This sensor is not affected by the presence other gases such as carbon monoxide, methane and hydrogen sulphide,” said Fraser.

The sensors are protected against corrosive gases by H2Scan’s proprietary coating, which gives the Hy-Optima 2700 an operational lifetime of at least 10 years.

A further advantage of the Hy-Optima 2700 is that the instrument is housed in an explosion-proof casing, which meets stringent international ‘Zone 2’ safety standards. This instrument will report through electronic connections to an existing SCADA-type control system.

“Traditional monitoring methods rely on sampling and the use of gas chromatographs, thermal conductivity meters and density analysers. These monitoring methods are both costly to install and maintain. The time from sample extraction to results can be quite long, which robs process engineers of the opportunity to monitor in real-time.”

Fraser said that accurate hydrogen monitoring by the Hy-Optima 2700 will, however, ensure that refineries not only produce consistent high-quality products, but also protect their complex and costly plant against damage.

“For example, very expensive catalysts are used to break down the long chain molecules in the heavier fractions. If the levels of hydrogen in the process stream are too high, there is too much energy present, which can damage catalysts. If there is insufficient hydrogen, the process slows down, potentially costing the refinery a significant amount in downtime.

“In addition, accurate hydrogen monitoring can also significantly extend catalyst life resulting in substantial operational savings.”

The Hy-Optima 2700 can be used to monitor a number of other post-fractional distillation refinery processes such as reforming, cracking, recycle, tail gas, fuel gas, flare gas and other multi-component process streams. The Hy-Optima range of instruments can also be used in other sectors, such as in the supply of natural and industrial gas.

There are, in addition, extensive applications in the petrochemical industry to monitor polymer feeds and flare gas process streams, or in the manufacturing sector, in metals annealing, semiconductor, oil hydrogenation and fertiliser manufacturing process streams.

With real-time hydrogen monitoring, process engineers have an overview of exactly what is taking place in any complex refinery process stream. This means early detection of any problems and, ultimately, the refinery is able to produce better products more economically. Improved energy efficiencies result in reduced maintenance and downtime costs.

“Oil refining is a high stakes business. If a refinery finds it is experiencing challenges either with low production or poor product quality, it needs to look at the accurate control of hydrogen in the various process streams,” said Fraser.